Selection and Coupling:

The development of a chain can be measured in order to control its degree of precision and verify that it corresponds to the reference standards. This measurement is carried out on assembled and non-lubricated chains and differs for each type as follows:

- Short-pitch precision chains: the reference standard is ISO606 which allows a deviation from the nominal value up to 0, + 0.15%;

- Long-pitch precision chains: the reference standard is ISO1275 which allows a deviation from the nominal value up to 0, + 0.15%;

- Heavy-duty conveyor chains: the reference standard is ISO1977 which allows a deviation from the nominal value up to 0, + 0.25%;

- Agricultural chains: the reference standard is ISO487 which allows a deviation from the nominal value up to 0, + 0.3%.

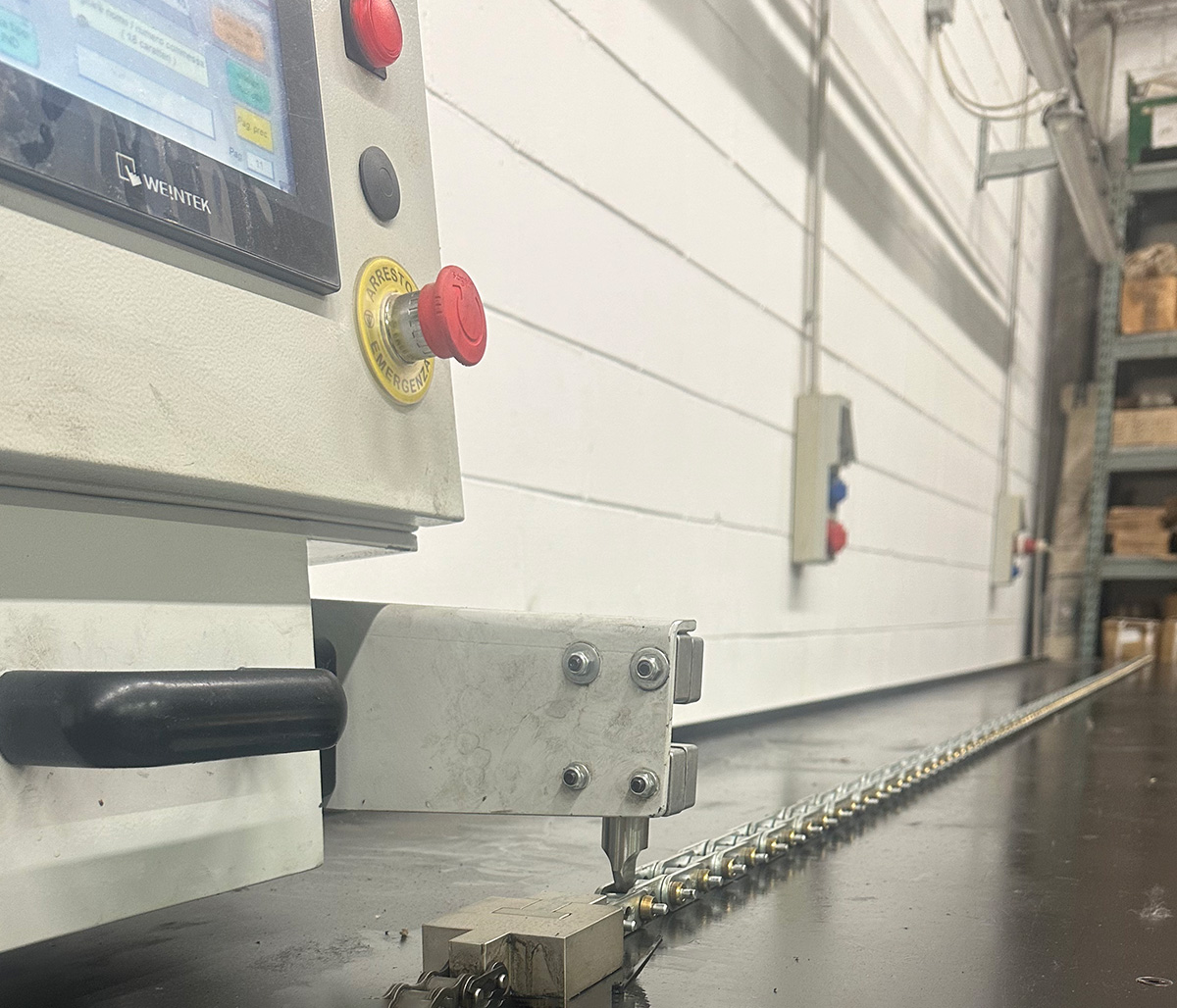

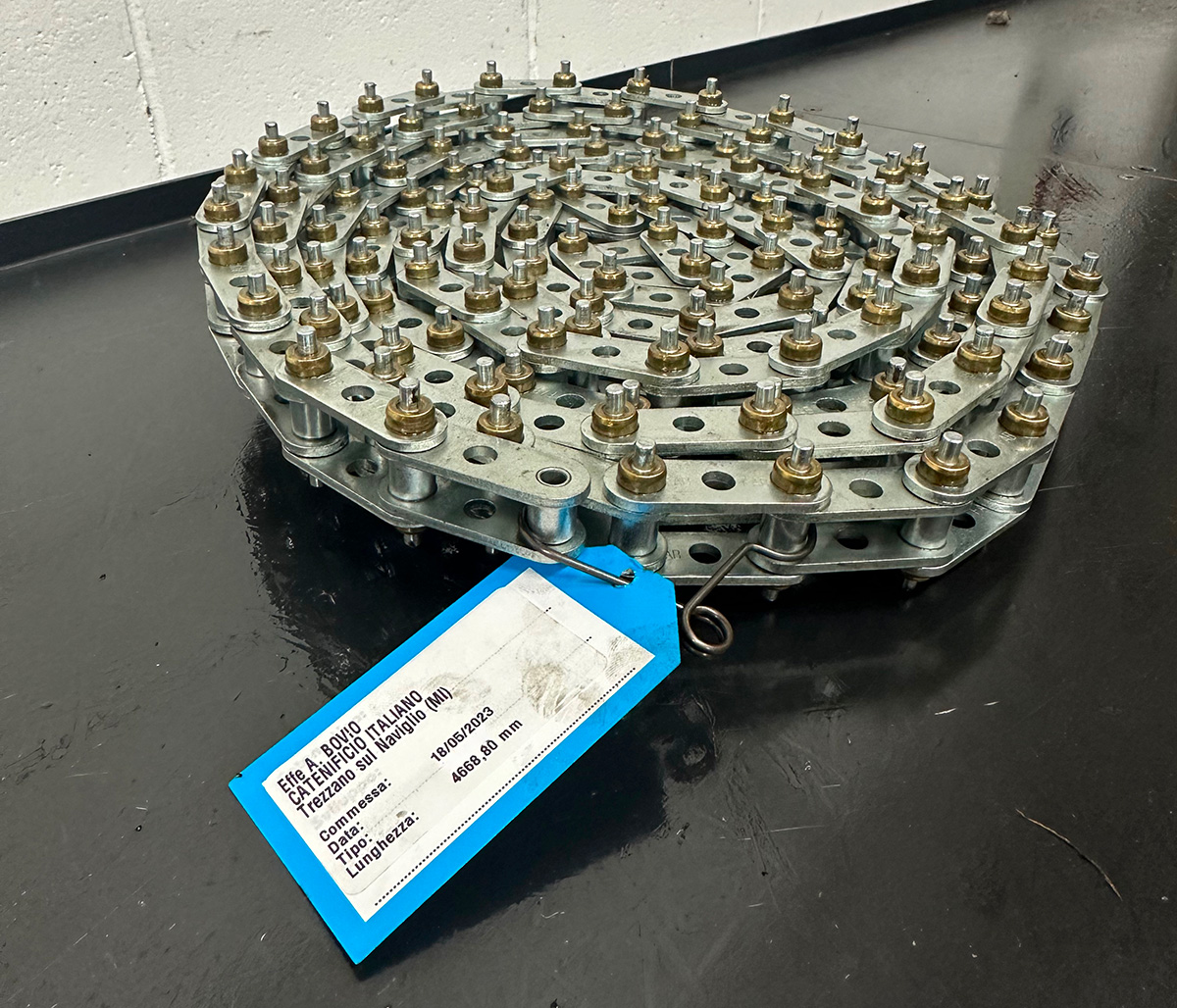

Coupling is a fundamental and necessary operation for all applications in which two or more chains will have to work side by side and consequently, for their correct use, they must be selected to ensure a higher level of precision. This operation is carried out internally by us with modular traction benches which, through optical fiber and a probe, detect the length of each chain branch with a precision of 0.01mm. Each individual branch, divided according to the tolerance range established with the customer, is labeled to allow for correct and intuitive final assembly.